DC (Decent Cheap) Throttles

For the few of us remaining who have no need or want for DCC, and would like a simple, safe and economical DC throttle that's relatively easy to build, here's what I've been using for the last decade or so.

What makes them so cheap? The controls are made for dimming LED strip lighting, which is all the rage on eBay, with lights and dimmers going for next to nothing, delivered directly from China. Assuming you already have a DC source, you can build one for as little as $5, and no more than $15. Plus, it delivers performance comparable to commercial throttles costing five to ten times as much.

What makes them so good? These units control LED brightness—as well as small motor speed—using "pulse width modulation." PWM controls deliver pulses of a specific size and shape that are the most ideal, efficient and safe for use with small DC motors—even delicate coreless motors.

Another advantage of these controllers is that they will function on a wide range of DC supplies, from 9 to 24 volts, depending on your needs. You can use batteries, wall warts or most any other filtered DC source. I happen to prefer batteries because, if your layout is small, it becomes totally portable. It's also a safe way to go: batteries deliver perfectly clean, noise-free DC.

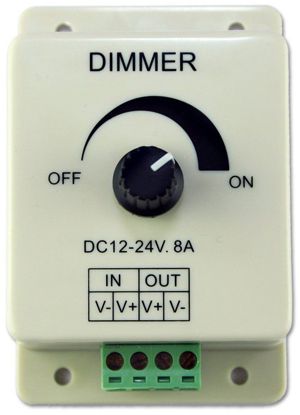

The controllers are quite robust, with a maximum load rating of 8 amps—more than what modelers typically need. They're also tough: a dead short doesn't seem to bother them. (See my caveat at the bottom of the page.)

What You'll Need

An LED dimmer. These can be had on eBay for as little as three bucks, shipping included. Just do a search for "LED dimmer" and look for one of these (below left):

A DPDT center-off switch. You'll need one of these (above right) because the LED dimmer doesn't allow you to control the output polarity; in other words, you can't reverse the loco. These are available almost literally for pennies a piece; one listing I saw recently offered five of them for a buck and a half, with free shipping.

A power supply. As I'd indicated, I prefer battery power; typically I'll use a six-cell (9 volt) or eight-cell (12 volt) AA holder (below left), depending on the load. These can be had for a buck and change. I've also used wall warts and DIY supplies; it doesn't matter. I've even used 9V "transistor" batteries, which work fine except that they don't last very long.

A plastic electronics enclosure (optional). You'll need one if you want a hand-held control (above right); they can be found for $2-3. If you don't mind a slightly bulkier unit, you can roll everything—battery holder, dimmer and all—into a single enclosure for a totally self-contained throttle/supply. This has the added benefit of requiring only a two-conductor wire between the throttle and the layout.

A SPST switch (optional). Depending on you choice of power supply, you may want to be able to shut it off; they're sold for pennies apiece (below left).

KISS variation. I like to make things as simple as possible, and so I eliminate the power on-off switch by replacing the DPDT center-off direction control switch with a 3PDT center-off switch (above right) wired to cut the power supply when it's in the center position. They cost about a buck.

Miscellany. Naturally, you'll need some wire; you can use just about any stranded wire in the 24-18 gauge range, even "zip cord" or speaker wire. If you want to get fancy for handheld units, look for coiled four-conductor wire. Also, a bit of double-stick foam tape makes simple work of securing the electronics inside an enclosure.

Wiring

Here's the wiring diagram for a typical throttle:

As I'd mentioned, I like to integrate the power switch into the direction switch, and here's what that version looks like:

Note that this scheme makes use of the fact that the V+ IN and V+ OUT terminals on the dimmer are electrically tied together, which simplifies the wiring.

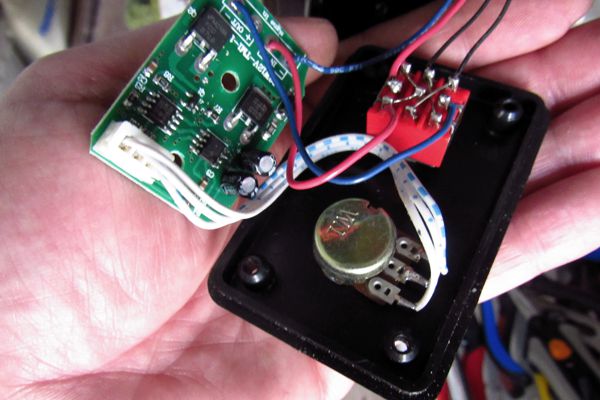

And here one is assembled:

Installation

There are many ways to install these throttles. Self-adhesive Velcro tape provides a convenient way to mount handheld versions; on my last home layout, I ran a strip along the entire fascia so I could hang them anywhere.

For small portable layouts, I'll physically incorporate a throttle into the layout. The most straightforward method I've used is to simply screw it to the base. On another layout, I installed the components right in the control panel; and on this one, where there was no room for a control panel, I built the throttle into the roof of an industrial structure, and disguised the controls as tanks and vents.

Questions Answered

What happens with a short? I cannot guarantee they'll survive a short circuit with the throttle wide open for an indeterminate amount of time; all I can say is that I've accidentally shorted them out for brief periods, while powered at 9-12 volts, and never had an issue. If you're worried about a $3 dimmer, add a circuit breaker. (You'll probably spend more on the breaker than the throttle.)

What is the frequency of the PWM? I don't know. I can report that it doesn't create any audible noise in loco motors that I've been able to detect.

Why don't you make them for sale? I may just do that one day. For now, please enjoy the satisfaction of building your own.